From Temporary Fix to Perfect Solution: Building a Better Drill Press Fence

For months, I made do with a makeshift fence on my drill press table—just a straight piece of plywood secured with two T-track clamps. While functional, it had its frustrations. Every time I tightened the clamps, the fence would shift slightly. Positioning it felt like a juggling act (where's that third hand when you need it?). Plus, it lacked an integrated stop block and took up too much space. Let's be honest—it wasn't exactly easy on the eyes either.

The Game-Changing Realization

Here's what really changed my perspective: I discovered that a drill press fence doesn't need to be square to the table. Why? Because you're working with a single point of impact—the drill bit. Once you set the fence, the distance between it and the bit remains constant. Move your workpiece along the fence at any angle, and that critical distance stays exactly the same.

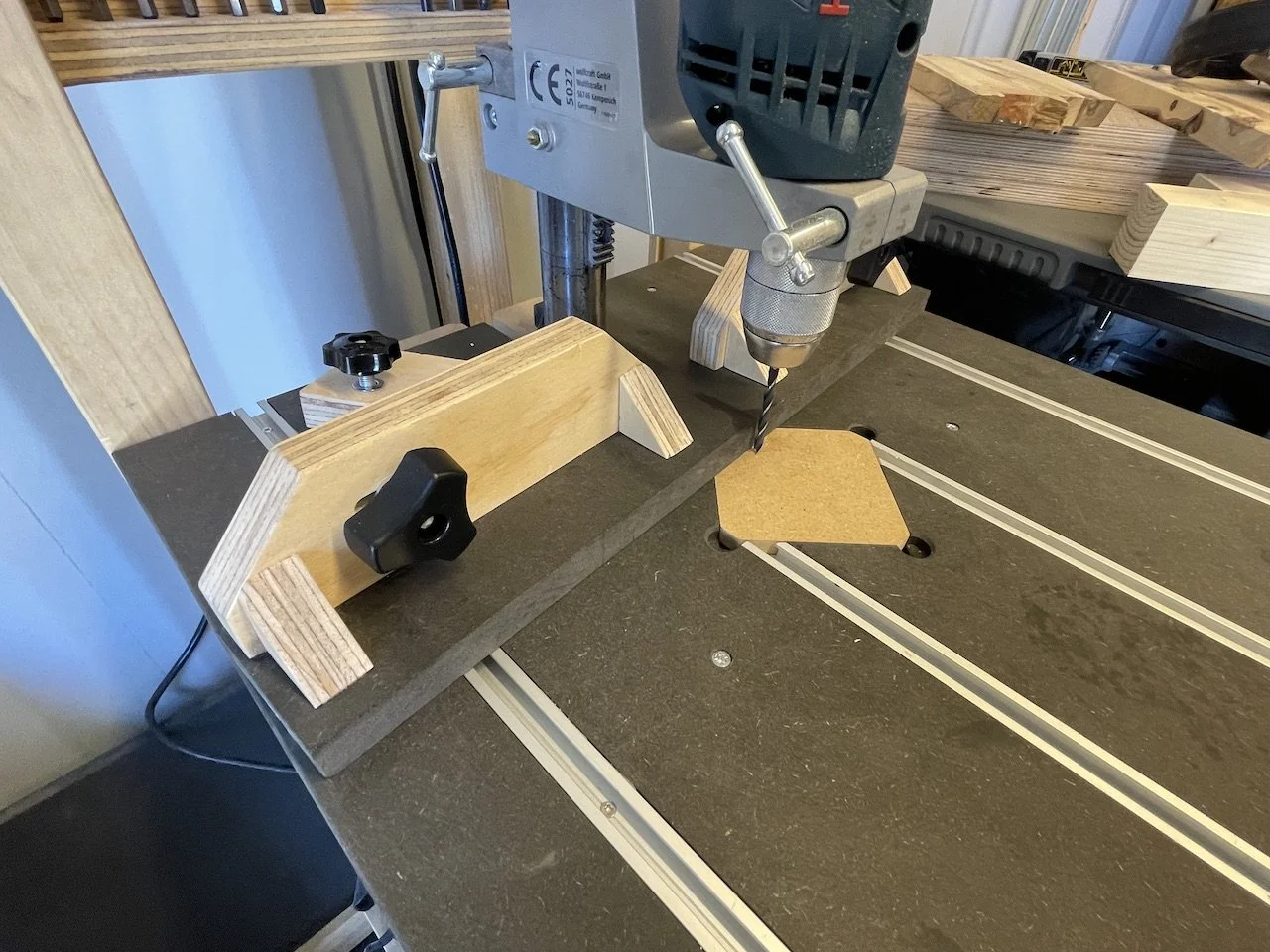

This insight led to my first major design improvement. Instead of a simple hole for securing the fence, I cut a slot that allows for angular positioning. Now I can adjust the fence to any angle that best supports oddly shaped workpieces while maintaining precise drilling positions.

Design Refinements

Several thoughtful details make this fence truly practical:

The T-track placement was carefully considered. Rather than mounting it on top of the fence, I positioned it on the front face. This might seem like a small detail, but it makes a huge difference. With a top-mounted track, a manufactured stop block could limit how close you can drill to it. My solution? A simple piece of plywood, carefully squared, with an M8 screw and a plastic knob. Simple, yet incredibly functional.

The fence rides on two rear support gliders, which work in conjunction with those slots I mentioned earlier. This combination makes positioning and securing the fence remarkably smooth and stable—no more wrestling with shifting positions during tightening.

The fence is relatively tall. In case a lower fence is needed because you need to work very close to the fence I’m considering to cut two additional slots into the face of the fence, which allows me to flip it and use the low top edge for such cases.

Was It Worth It?

You might wonder if upgrading from a temporary fence was really necessary. Could I have continued with my makeshift solution? Sure. Would it have done the job? Mostly. But here's the thing: when you use your drill press as frequently as I do, these small improvements add up to a significantly more enjoyable working experience.

The fence isn't just about precision—it's about making the work flow smoothly, reducing frustration, and yes, adding a touch of pride to the workshop. Sometimes, it's these seemingly minor upgrades that make a difference in day-to-day work.